Error: Contact form not found.

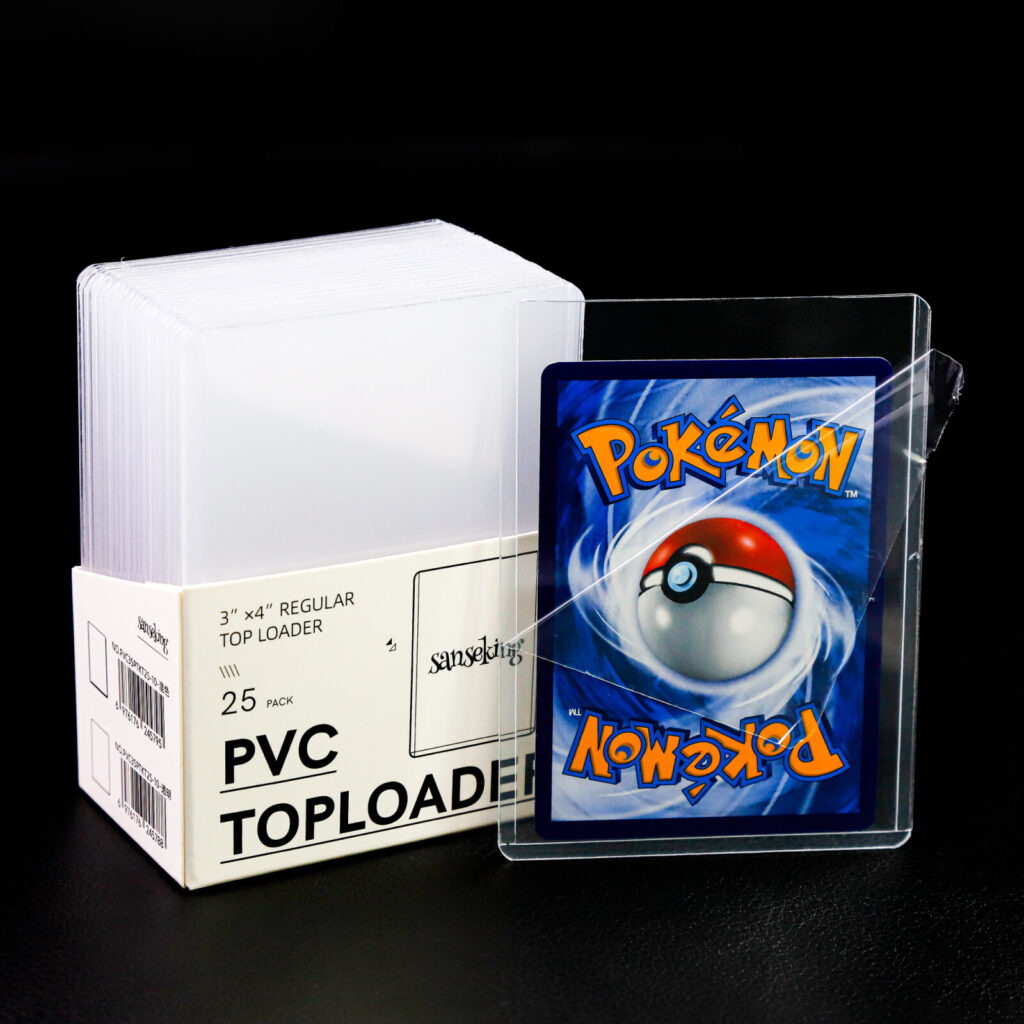

As an Amazon seller in the Trading Card Game industry, the material you choose for your card holders plays a critical role in both product quality and profit margins. PVC and PET are the two most commonly used materials in the card holder industry. Understanding the advantages and trade-offs of these materials can help you make a cost-effective decision that maximizes profitability while maintaining product quality. In this article, we will take an in-depth look at both PVC and PET from a supplier’s perspective, considering key factors like material characteristics, production costs, long-term storage, and market positioning to guide you in choosing the best option for your business.

When choosing the right material for your card holders, a detailed understanding of the material characteristics is crucial for making a decision that balances performance and cost. PVC and PET each offer unique features, and the differences between them can have a profound impact on the overall product quality, customer satisfaction, and profitability. Let’s take a deeper dive into these two materials from both a technical and market-oriented perspective.

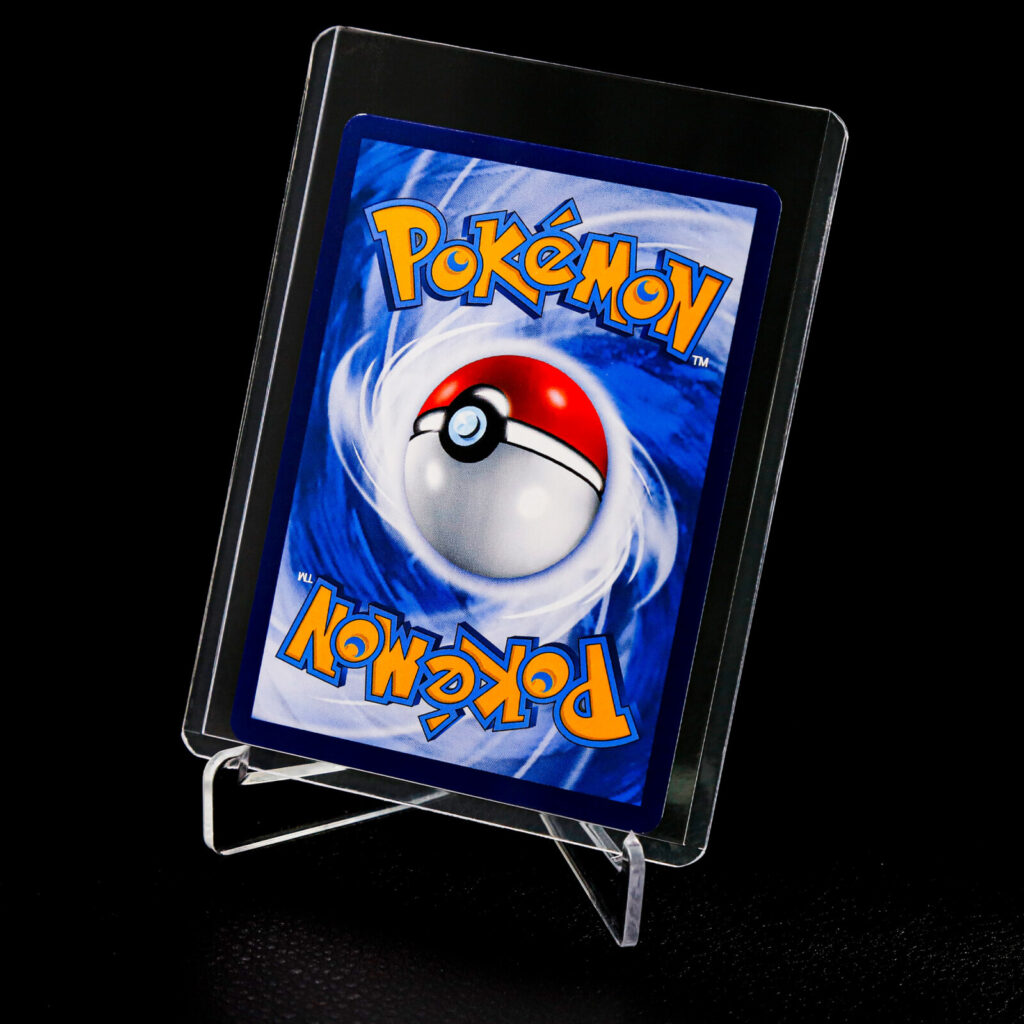

As previously mentioned, PVC holds around 60% of the card holder market share, largely because of its cost-effectiveness and versatility. Below, we’ll explore some additional strengths and limitations of PVC that influence its performance and usage in card holders.

Both PVC and PET offer valuable advantages depending on your business model, target market, and product specifications.

1.PVC is best for budget-conscious sellers who need a flexible, cost-effective material that offers decent protection. It is ideal for high-volume sales in markets where card presentation is not the primary concern. PVC is also advantageous for short-term storage and products with a fast turnover rate, as it allows for lower production costs.

2.PET is the go-to material for premium products, particularly in high-end or collectible markets. Its superior clarity, higher strength, and long-term durability make it a better option for products that require a higher level of protection and presentation. While it comes at a higher price, the added value can justify the cost, particularly for sellers targeting customers who are willing to pay more for premium protection.

In conclusion, the decision between PVC and PET should be based on a comprehensive evaluation of your target audience, production needs, and long-term business goals. For businesses aiming to offer high-quality, long-lasting products that stand out visually, PET is the superior choice. However, for sellers focused on affordability and high turnover, PVC offers a solid, cost-effective alternative.

At first glance, PVC appears to be the cheaper option—15%-20% less expensive than PET. This price difference may seem significant, especially for bulk purchases. However, when making procurement decisions, focusing solely on the material cost overlooks other hidden factors that can affect your overall profitability.

One critical factor that directly influences the cost-effectiveness of PVC vs. PET is production yield. PET materials have an 8%-10% lower production waste rate compared to PVC. This means that with PET, the same quantity of raw materials will yield a higher number of usable card holders. The increased thermal stability of PET reduces scrap during the manufacturing process, which ultimately leads to higher efficiency and lower overall production costs.

Thus, while the initial price of PET is higher, the actual cost of producing a finished card holder is often lower because there is less material waste, increasing your profit margin in the long run.

A key factor to consider when making a material selection is how the card holders will perform over time, especially if you are storing inventory for extended periods. PVC card holders are prone to plasticizer migration over time, which can cause the material to cloud or become hazy. This problem typically arises after several months or years of storage, especially under high-humidity conditions. If you are holding inventory for a long period, this can lead to significant product degradation and customer dissatisfaction.

PET, however, does not face this issue. PET's chemical stability ensures that it will not undergo the same degradation, making it the superior choice for sellers who plan to store card holders for extended periods. This longevity reduces the risk of devaluation in your inventory and helps protect your bottom line.

Now that we’ve compared PVC and PET in terms of characteristics and costs, let’s break down the key factors that should influence your decision-making process when selecting the right material for your card holders.

Your target market plays a major role in determining whether PVC or PET is the better material for your card holders.

By aligning your material choice with your market positioning, you can optimize your pricing strategy and appeal to your specific customer base.

Another important consideration is your product's turnover rate—whether you expect to sell it quickly or hold it for an extended period.

Transportation and handling are other crucial factors when deciding between PVC and PET. If your card holders are going through long-distance or complex logistics, PET’s higher rigidity provides better protection. The added strength ensures that the card holders can withstand more pressure and impact during shipping, reducing the likelihood of damage.

Studies have shown that PET card holders can reduce the rate of damage by 25% compared to PVC in long-distance shipping or environments with rough handling. This can ultimately save you on return costs, customer complaints, and warranty claims.

In conclusion, selecting the best material for your card holders requires a nuanced approach that balances both the short-term and long-term needs of your business. Here’s a recap of the advantages and considerations for each material:

Ultimately, there is no one-size-fits-all solution. By considering your target market, inventory turnover, storage conditions, and shipping requirements, you can make a more informed decision that maximizes your profitability. Working with a professional supplier who can provide accurate material specifications and high-quality production standards is crucial to ensuring that the material you choose delivers the best possible performance.

Incorporating small batch testing and real-world data will give you the insights you need to make the right decision for your business. The goal is to select a material that aligns with your objectives while offering the best balance between cost, quality, and long-term profitability.