Error: Contact form not found.

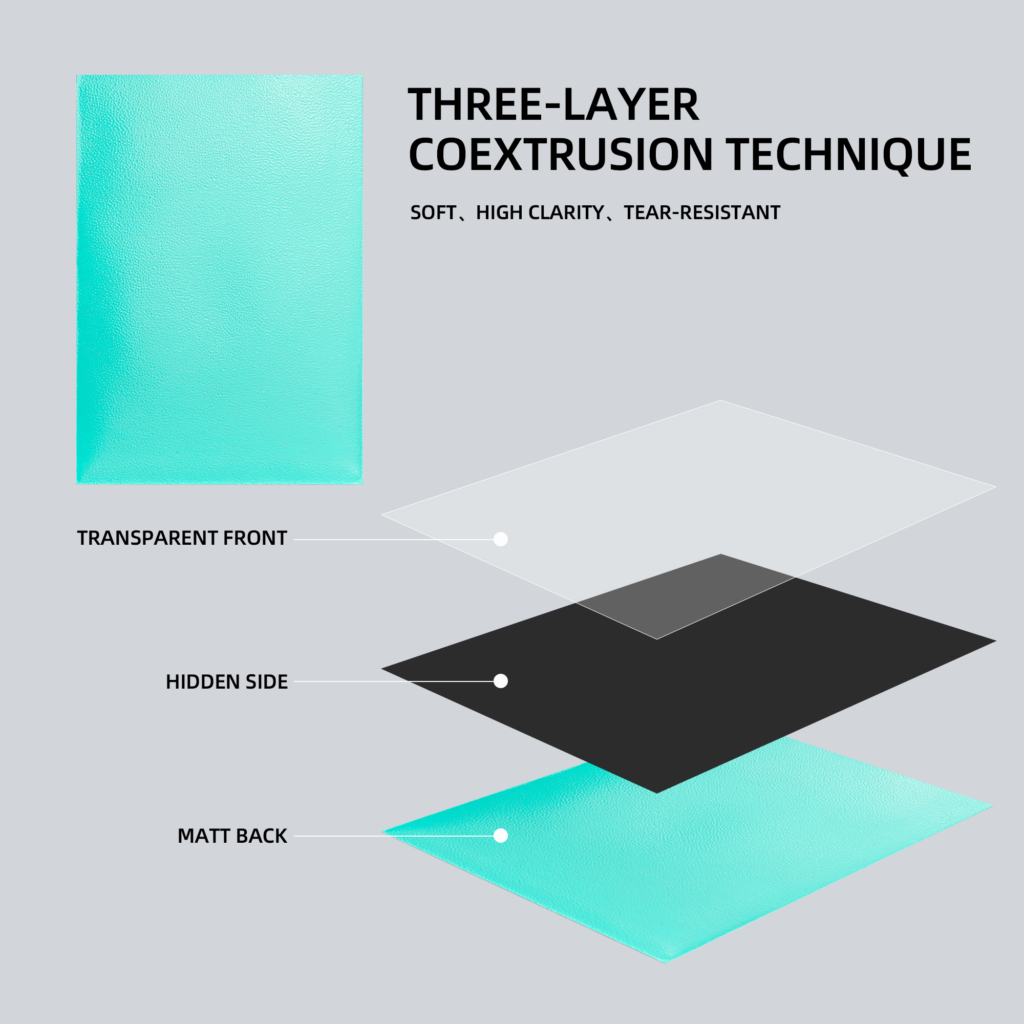

As a manufacturer of card sleeves for 11 years, Sanseking continues to serve as an OEM for major TCG peripheral brands worldwide. We have made significant innovations and optimizations in card sleeve production technology, becoming the world’s first producer of three-layer co-extruded PP film material. This advancement has completely eliminated the issue of card backs being visible through the sleeves. Today, we would like to share insights into the production of card sleeves from a manufacturing perspective, focusing on the materials and the differences in craftsmanship.

First, let’s discuss the basic transparent ultra-clear inner sleeves, which provide fundamental card protection. Usage scenarios include serving as the first layer of protection for TCG and sports cards.

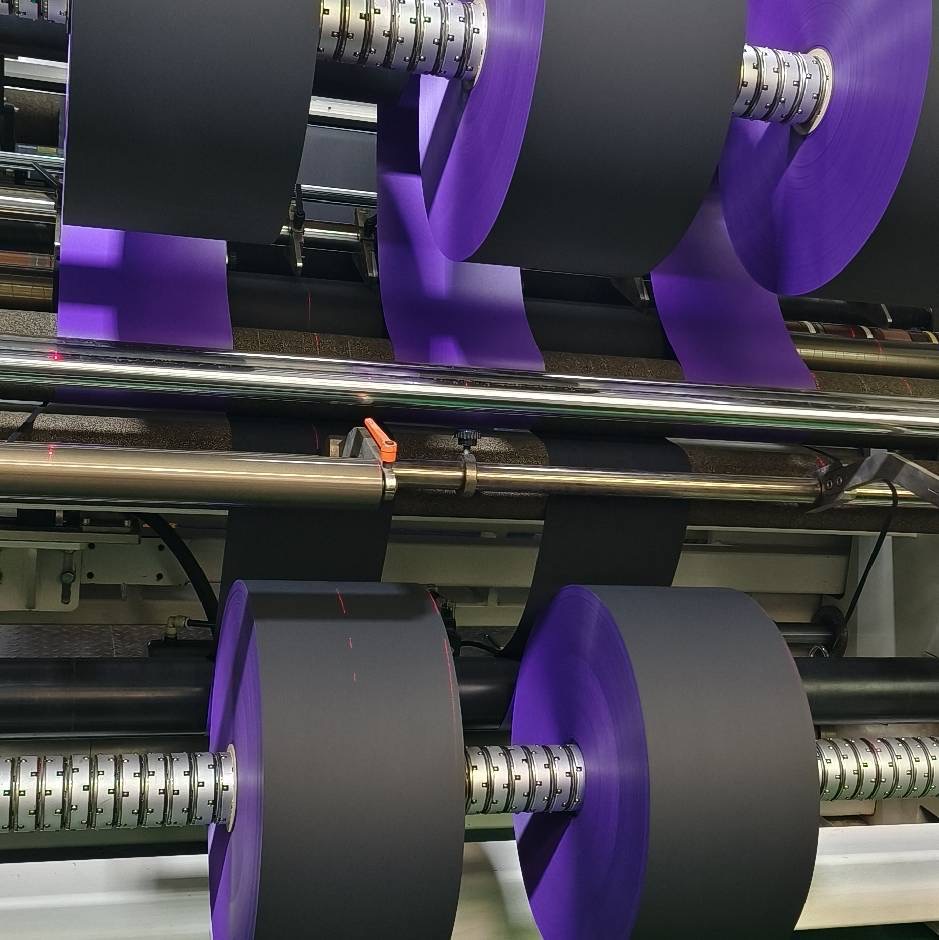

The core material for transparent inner sleeves is PP (polypropylene) granules, which are melted at high temperatures to become liquid. This liquid is then blown and cooled into roll stock material. The automatic slitting machine cuts this material into card sleeves. The key points for the inner sleeve film are a light transmittance of 90% and a specific haze percentage. The material must be fully melted without crystallization or defects, and the surface should be free of water wave patterns. Currently, the thickness of inner sleeves on the market is typically 0.05mm, and meeting these quality standards requires a certain level of technical expertise. When purchasing inner sleeves, you can check for quality based on these criteria.

Solid TCG card sleeves are essential for tournament card game enthusiasts. They are one of the most important products in our core TCG peripheral series at Sanseking.

The main material for opaque tournament sleeves is 95% PP polypropylene granules. Transparent PP granules are mixed with colorants (color masterbatch) in a container and melted at high temperatures to form a liquid. This liquid is then co-extruded in three layers to produce roll stock material that prevents visibility of card backs. Finally, an automatic slitting machine combines and welds the opaque color layer with the transparent ultra-clear layer, completing the standard tournament sleeve production.

The key points for tournament sleeves include the material's tactile comfort, the smoothness during shuffling and cutting, and the pleasant texture of the surface that should be non-sticky. Additionally, the durability of the sealing edges is crucial, it should not easily tear or crack. Tournament sleeves must also comply with TCG tournament regulations, requiring that all card sleeves in a deck be of consistent color with no noticeable color differences. The edges of the sleeves should not display significant variations in cutting marks. Lastly, the color layer of TCG tournament sleeves must not allow light to pass through, revealing card backs. As one of the most important accessories for TCG, Sanseking continuously innovates in material technology, applying advancements from new energy battery insulation technology to the TCG community.

Additional Products

In this series, we also offer matte ultra-clear outer sleeves and transparent rounded corner matte sleeves designed for board game cards!

Art sleeves are the most complex among our three products, offering the greatest potential for customization. Based on design files, we utilize various material combinations to bring the design to life. The processes involved include:

1. Laser film hollow creative designs.

2. Metallic aluminum film combined with OPP for color printing

3. Full color printing.

The first step is to convert the design files into four color CMYK templates. The patterns are then printed onto the selected materials using a four-color water-based printing machine. The color printing layer is composed of a combination of PP film, OPP film, and PVC aluminum film, which together create the colorful layer. An automatic slitting machine is then used to combine and weld the completed printed color roll layer with the transparent layer, finalizing the production of the art sleeve.

As one of the most popular accessories for various card game IP, art sleeves play a significant role in expressing the influence of major IP, as well as being a favored means of expression for card enthusiasts. The core element of art card sleeves lies in the presentation of the printed designs. However, the thickness of the material and the production processes limit the use of modern UV printing technology. Currently, the printing for art sleeves employs traditional gravure printing techniques.

Therefore, the key to achieving high-quality printing is ensuring precise registration during the color separation printing process. This precision ensures accurate color values, high saturation, minimal dot gain, and high image fidelity. These requirements place demanding expectations on the operators and the press setup in the factory. Only by meeting these conditions can we create exquisite art sleeves.

1. Dimension Accuracy: The size must not deviate by more than 0.01mm.

2. Art Printed Sleeves: No size borders should appear, and the design must be centered.

3. Materials: No crystalline particles or scratches should be present on the material.

4. Competitive Sleeves: The color layer must not be transparent, preventing visibility of the card backs.

5. Transparent Layer: The light transmittance of the transparent layer must reach 90%.

6. Edge Durability: The edge sealing must withstand a tensile strength of 13 lbs.

7. Smoothness: The sleeves should allow for smooth card insertion without blockage or stuttering.

8. Color Consistency: Different batches of the same color code must be consistent, with no color variation.

9. Cut Edges: The edges must be smooth, and the sleeves should not curl or lift.

10. Color Adhesion: The colors on art printed sleeves must adhere securely, with precise CMYK registration, no dot gain, and solid lamination.

Welding Tensile Test

Transmittance and Haze Test

Even your cards are with card sleeves, daily maintenance should not be overlooked. Prolonged use may lead to scratches or stains on the surface of the sleeves, at which point you might consider replacing them. Additionally, when storing cards for an extended period, they should be kept in a dry, cool environment, avoiding direct sunlight and excessive heat to prevent deformation of the sleeves or moisture damage to the cards.

For particularly valuable cards, I recommend placing them in a dehumidifying box or a special collector's case. This not only prevents moisture and dust from entering but also protects the cards from physical damage.

In summary, card sleeves are an indispensable tool for card collection and usage. By selecting and using sleeves wisely, we can effectively protect our cards, extend their lifespan, and maintain their value. As a collector, I understand the importance of safeguarding each card, and sleeves are undoubtedly the best assistants in achieving this goal. I hope my sharing provides some helpful insights, making everyone's collecting journey smoother and more enjoyable.